Navrattan Green Crete

Navrattan Green Crete

Navrattan Green Cement Industries Pvt. Ltd was conceived with a strong notion to create such alternative ways of energy generation which are high performance, sustainable and Green. The company is producing ‘Geopolymeric’ cement that is Eco-friendly cement that transforms an enzyme of the algae into a highly concentrated Elastic Polymeric powder.

The most significant advantages of Navrattan Green Crete is its momentous reduction of CO2 emission into the atmosphere, affordability, increased strength, and durability, good compressive strength and impermeability, does not corrode as compared to traditional OPC thereby reducing the environmental impact and lowering the cost. NGCIPL’s business strategy is centered on providing green concrete products that conserve energy resources, reduce pollutants and bring green foundations to all type of concrete constructions.

Description

The Navrattan Crete is stronger that a conventional cement and has three times the compressive and tensile strength of Portland cement and requires significantly less energy to produce, thus leaving a substantially smaller carbon footprint.High performance green buildings built with green materials like Navrattan Crete use less, waste less and produce less green house gas emissions than conventional buildings. The Navrattan Crete is environment friendly, sustainable, reliable, durable and affordable.

Buildings are one of the heaviest consumers of natural resources and account for a significant portion of the greenhouse gas emissions that affect climate change and is definitely not sustainable. Portland cement is the most common type of cement used worldwide and is the biggest target for reducing the CO2 footprint of building materials.

Navrattan Crete uses many of the same materials used in blends with traditional Portland cement. However, the major difference comes from the fact that Navrattan Crete isn’t produced with quarried limestone product. Limestone creates an excessive amount of CO2 by virtue of the fact that extreme heat is used to create the cement. Navrattan Crete uses a proprietary catalyst/binding agent that is combined with materials containing alumina silicate that can allow the cement to be produced at ambient temperatures, from sub-tropical to below freezing, meaning that it takes 80 to 90% less energy to produce and dramatically lowers the CO2 released into the atmosphere.

Structural Qualities

The Navrattan Crete has a wide range of Structural Qualities as compared to Ordinary Portland Cement. Few of the vital differences are listed below

- Navrattan Crete has a strengths that can be adjusted to compression requirements.

- Navrattan Crete(NC) has higher Tensile strength than Portland Cement (OPC) due to its intrinsic covalent bonding nature.

- NC meets as well exceeds all the same tensing standards as OPC and excels in every category

- Navrattan Crete has a low coefficient of expansion which facilitates it to work in freezing or tropical regions of the world.

- Navrattan Crete is hydrophobic and therefore highly resistant or impervious to water, acids, corrosion, sulfates or more which makes it perfect to use for waterproof basements, pipe coatings, countertops, waste water tanks, fish farms, docks etc.

- NC absolutely stops oxidation ensuring no more rusty bars in your structure as compared to that of OPC making your structures more sustainable and longer lasting.

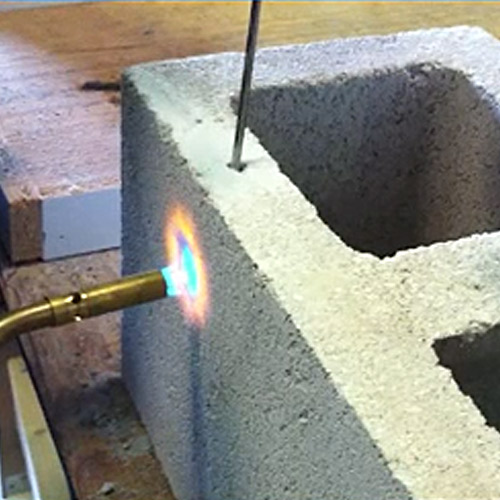

- NC binder gives the cement super insulating abilities that results in almost no heat transfer no matter what aggregate is used – including cellulose or rock. Portland blocks would probably explode with that much heat

- Navrattan Crete will not dry or crack skin as lime based OPC does.

- Navrattan Cement is less expensive to produce than Portland Cement and no fossil fuels or heating of materials are needed.

Benefits

According to the World Business Council for Sustainable Development, cement manufacturing is alone responsible for 5% of global CO2 emissions.

- Low carbon footprint.

- Highly-Resistant to water, acids, corrosion, sulfates and more

- Can be handled and worked with in 3 to 7 days

- Very slow, if any, transfer of heat. R factor of 70+. Great for insulating and fire retarding/proofing

- Set times can be custom set (example: 30 min to 4 hrs or in extreme cases even longer)

- Custom design client’s end product with our technology

- Can be used as a coating to protect, insulate and enhance existing Portland structures and other material, even wood. It can be painted, rolled, or used in a Gunite gun.

- Is less expensive than Portland, but works just like Portland.

- Pour into casts and remove cast after 4 hours.

- Covalently bonds to almost anything on a molecular level